Ductwork Cost Breakdown

The Fair Market Price for a Colonial SFH Installation is between $24,500 and $34,000.

Update: with the move to R-32 and R-454B equipment,

This spring, we’ve spent a lot of time thinking about ductwork. There’s a lot of cost variation when it comes to ducted systems, and it’s been a black box for us.

Today, we finally pull back the curtain. We’ll account for the cost of physical material, move onto labor costs & overhead, and add all of that up for a final cost expectation.

Executive Summary

Equipment: $8,000 to $10,000

Consumables: $3,500 to $5,000

Labor: $5,500 to $7,500

Overhead: $6,500 to $8,500

Profit: $1,000 (not very realistic) to $4,000 (more realistic)

Total: $24,500 to $34,000. Average $29,250.

Categorization & Installation Details

First things first. Broadly, we encounter 2 types of ducted jobs:

New ductwork (ductwork doesn’t exist yet, but you want to add it)

Reusing existing ductwork

Today, we’ll be talking about Case #1, new ductwork. And we’ll be talking in the context of a colonial single family home attic installation, one of the most common types of installations we see in the Boston metro area.

For this installation, we’ll need:

Outdoor unit

2 Ductless mini-splits for the 1st floor

1 Air Handler in the attic conditioning the 2nd floor

Ductwork & consumables

Raw Materials

Equipment

This is the heat pump itself. This is the stuff that’s branded, aka Mitsubishi, Daikin, LG, Samsung, Fujitsu, etc. The prices here are highly dependent on the brand, as well as the ordering volume. Larger accounts at supply houses (or with manufacturers) get better discounts, and that’s one reason why none of the supply house websites have public pricing displayed1. Certain supply houses themselves may also have higher or lower prices, corresponding to factors such as delivery reliability & equipment availability.

Below is a sample list of equipment for Mitsubishi equipment if you’re a small/medium contractor and you buy straight from the warehouse, which is a good market price ceiling. It comes out to right about $10,000.

For non-Mitsubishi brands, feel free to apply a ~10% discount. In our bulk deals, we can negotiate for even deeper discounts, but I suspect this is an advantage that big HVAC contractors already have.

Consumables

This includes the cost of assembling ductwork, and running refrigerant/condensate lines, etc. Typically, you want to have extra consumables so you don’t end up needing to make a supply run mid-installation, which can add maybe 2 to 3 hours to a job (or longer, depending on how specialized the parts are).

The raw material cost comes out to ~$3,500. This scenario assumes that:

Supply & Return trunks are fabricated on-site: a lot of times, contractors will ballpark something like “$1,000 for a trunk, $500 per branch” which includes the labor cost that’s required to fabricate the trunk from the sheet metal. This analysis does NOT account for that.

Small/Medium-sized colonial single family houses: bigger houses with longer, more complicated flex duct and/or refrigerant line set runs will, obviously, incur greater costs for those materials. Here, we are assuming 75 ft of line set.

2 Mini-splits: if you had an additional mini-split, it would be maybe an additional 25 to 50 ft. of line set.

If you’re a contractor working in a really standard installation, you may opt to get prefabricated sheet metal components. These are typically a bit more expensive, but they’ll also save you a lot of time.

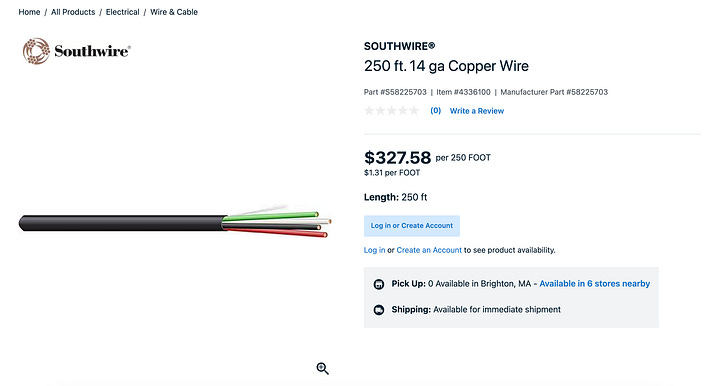

To show you that I’m actually referencing real numbers, here are some screenshots from the supply house website:

I’d consider this a baseline. If we were talking a larger or more complex installation, we’d go up from there and hit anywhere between $4,000 or maybe ~$5,000+.

Labor & Overhead Cost

Labor

Labor costs can vary widely. For us, a colonial single family home installation with a crew of 3 people (2 experienced, 1 less experienced) would take around 3 days to complete. And the installation labor cost would be from $4,000 to $6,000.

NOTE: you’re probably looking at closer to $6,000 if you account for the cost of constructing trunks from sheet metal.

But that’s just for the HVAC portion. The electrical portion is around $1,500, including materials. So in total, you’re looking at an installation labor cost from $5,500 to $7,500.

Overhead is a bit more complicated, however. It can vary widely.

Overhead

I’ll break it down into 3 factors:

Operational efficiency. Does the crew make 1 trip to the house with all the necessary equipment for the installation? Or does the crew make 5 back & forth trips to the warehouse (which sometimes can be an hour away) because they tend to forget parts? Do they order all the parts first, package it, then send it out with the installation team, or is the installation team driving to 3 different supply houses to get all the material required for the job? (Or, on a more basic level, is the crew experienced? A more experienced crew will get the job done faster.)

Contractor infrastructure & expenses. Every contractor will have the basics: vehicle, vacuum pump, manifold gauge, flaring tool. But does the contractor own a warehouse? If they do, that bumps up overhead but it also means that they can get equipment delivered ahead of time, which is good for material prep & logistics. And it also means they won’t ever run into a situation where the equipment delivery is late or damaged2. Or maybe they buy a ton of ads and billboards, and pass the cost of that marketing onto consumers?

Service quality. Does the contractor have a local, dedicated service team? Do they add a buffer for service calls? What’s their callback rate? If, for example, the electrical wiring is done incorrectly, they’ll need to send someone back to fix it; the more this happens, the more contractors would need to charge to cover this.

It’s really hard to tell how good contractors are at each of these unless you’ve worked with them before. Star ratings are inflated and I personally know that consumers typically use a 1-star rating/bad review as a last resort, which means a lot of service issues that pop up ultimately get resolved, but you never hear about them.

As a result, the best we can do is use this information to rigorously select for the best installation partners during our bulk deals. This is a legitimate limitation of our research model with the benchmarks, and one reason why the market for HVAC services feels so murky.

For us, administrative overhead - system design, logistics & ordering, customer Q&A, permitting coordination, salaries, rebates & HEAT loan paperwork, scheduling, service fund, etc. - come out to be ~$6,500. A more reasonable expectation is $7,500, which includes vehicles, transportation & installation equipment (e.g. manifold gauges & vacuum pumps).

More Details on Service

Compared to ductless installations, there are many more failure points associated with ducted installations. Here are few:

Thermostat issues (wiring, configuration, special settings)

Condensation line issues from air handler / condensate pumps

Balancing ducts & airflow (configuring dampers for optimal airflow)

Additional fan strain based on higher static pressure via. closed dampers

Of the $6,500 to $7,500 mentioned above, I’d say $1,500 is for service.

Profit

If the HVAC contractor is owned by private equity, expect there to be like, a huge additional amount going to net profit margin. If HVAC contractors on average are aiming for a healthy 20% net profit margin as a goal, Morgan Stanley/Goldman is aiming for like, 35%+.

After doing this for 2 years, I definitely think shops should be profitable. It’s tough work; long hours; doing this for a lifetime requires some sort of reward. I’ve personally been on a grad student salary (so Cambridge, am I right?), and in the future I’ll need more.

But for now, we are plowing all our profits into more research, & startup process development. Once we’re done with research & setting up processes, maybe we’ll actually turn a profit :)

In Total

Equipment: $8,000 to $10,000

Consumables: $3,500 to $5,000

Labor: $5,500 to $7,500

Overhead: $6,500 to $7,500

Profit: $1,000 (not very realistic) to $4,000 (more realistic)

Total: $24,500 to $34,000. Average $29,250.

And that’s why we price at $28,000 on our pricing menu for a baseline 2 mini-split + attic ductless installation for our bulk deals.

Okay, that’s it!

I’m tired. Gonna get some dinner. Hope this helps!

Cheers. Kit

It’s also why we aren’t screenshotting the supply house! Keep guessing.

If it is, at least they can get it replaced before a job.