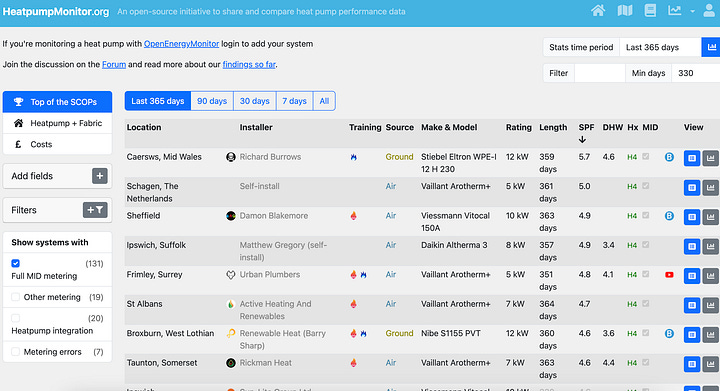

So we’ve directly project managed ~20 installations for research this spring at Laminar Collective. What did we learn?

We finally could report on a cost breakdown of ducted jobs, for one. Contractors never publish pricing breakdowns like this.

Ductwork Cost Breakdown

This spring, we’ve spent a lot of time thinking about ductwork. There’s a lot of cost variation when it comes to ducted systems, and it’s been a black box for us.

You know what contractors are even less likely to publish? An honest account of all the follow-up service calls they had to do. Usually, the best you can find is a marketing article that ends with

and that’s why [giant contracting company] offers great service. Get a quote today!

Ladies and gentlemen, in the name of transparency, here are the 3 big category of post-installation issues we’ve had to address this year.

Something Is Leaking

How to fix it: find the leak. It usually has to do with some component failing or not working. Replace the component. Pretty straightforward.

5 of our 20 installations had some sort of condensate leak after the installation. Fortunately, 4 of these were the exact same problem: a glue not holding the individual components of the EZ trap device together.

Fortunately, after spotting the first EZ trap issue, we immediately moved to fix the other 3, knowing that the same type of glue was used.

The final 1 out of 5 drainage issue had to do with a condensate pump that wasn’t plugged to a functioning outlet.

Takeaway: test the condensate pump upon commissioning. Consider asking residents to check on the condensate on particularly humid AC days.

Heat Pump is not Heating/Cooling Enough

How to fix it: varies. Depends on reason. Not as straightforward.

It’s 100 degrees today so we know this is happening. 3 houses out of 20 have some sort of an issue here, though 1 out of those 3 interestingly had too much cooling.

There are like, 5 potential reasons for this:

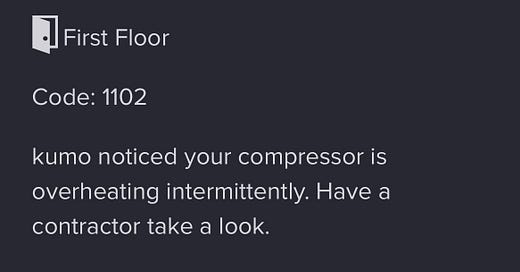

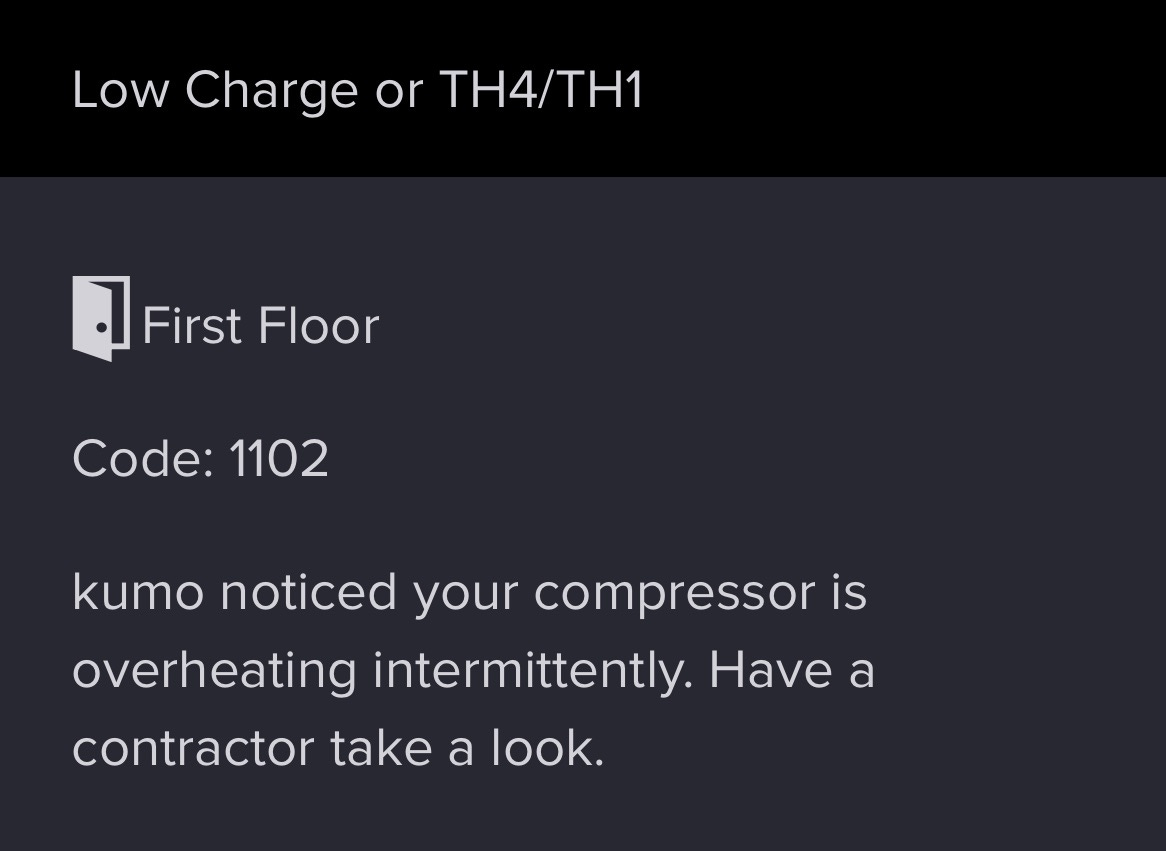

Refrigerant charge issue, like the one you see in the screenshot above. This can be due to 2 or 3 reasons, but the most likely one is that the refrigerant is low or there’s a leak.

1st & 2nd floor temperature differential. Cool air sinks and hot air rises, potentially leading to different temperature zones. If you cool the 2nd floor but not the 1st, the cold air will find its way downstairs.

Related: thermostat placement.

Insufficient weatherization. If you haven’t weatherized your house yet, you may have a draft coming in, and localized areas may feel uncomfortable. This is why Mass Save typically requires weatherization before heat pump installation.

Insufficient airflow/constricted ductwork. If the ductwork is too small, maybe it’s not delivering as much cool air as is necessary to cool the room. We try to hedge against this by doing ductwork performance testing on pre-existing ductwork.

Undersized equipment. This is rare. Typically, systems are oversized, and even if correctly sized, they are sized to the heating load (which is usually a lot more than the cooling load in MA).

During heat waves, HVAC contractors are more or less running around spending their entire day fielding “my AC isn’t working” service calls. This is part of the reason why prices are so high during the summer: contractors are less available.

Takeaway: test your system before summer heat waves! And make sure your contractor always does a pressure test & pulls a deep vacuum.

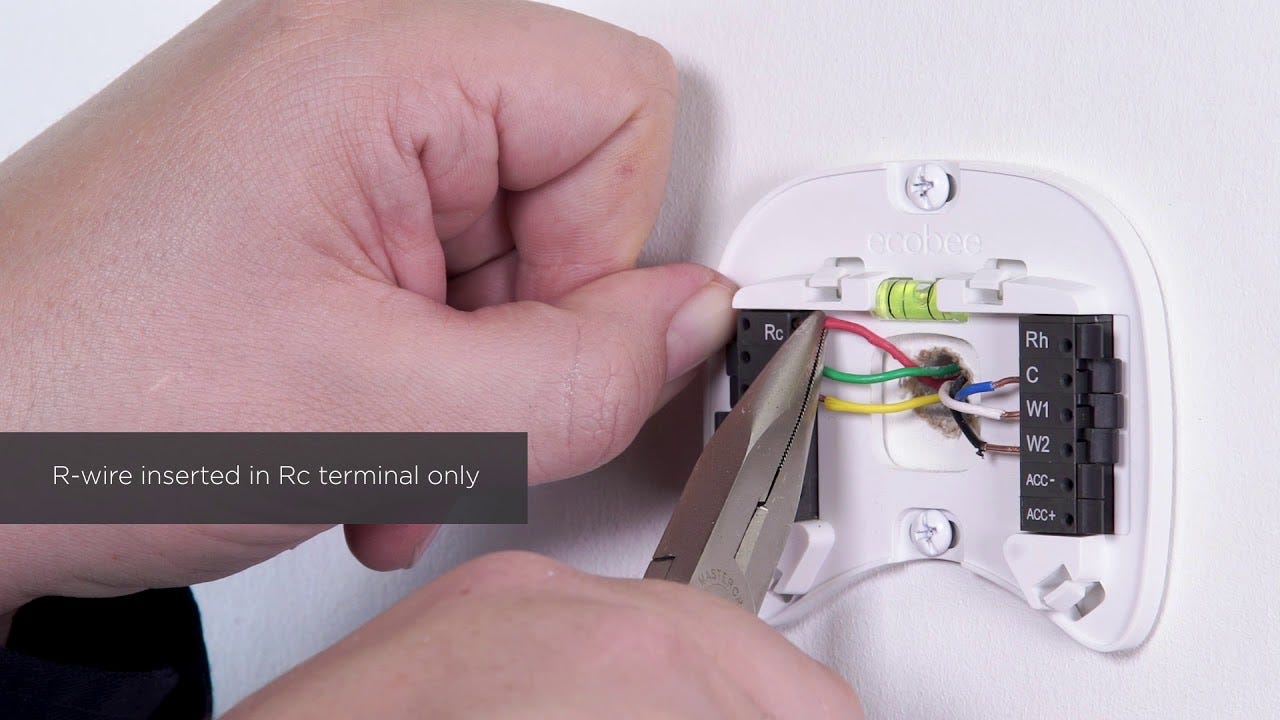

Thermostat/Electrical Wiring Issues

How to fix it: ensure the electrician/installation tech is familiar with the brand. Relatively straightforward.

We had 4 houses with these issues. They fall into 2 categories:

Thermostat isn’t connected / set up properly / missing an adapter

The indoor air handler unit1 wasn’t wired correctly

Different brands of thermostats & equipment (Ecobee, Daikin One, Mitsubishi MHK2) are configured somewhat differently than others. You’ll typically want to work with an electrician who is familiar with the system, or is great at sleuthing around installation manuals / talking with manufacturer technical hotlines.

For us, we found out that Daikin slim-ducted medium static air handlers (pancakes) required a specific adapter to connect to the Daikin One thermostat. Happened once, and then we ordered a bunch just in case. In one case, the electrical wiring got switched between 2 different air handlers - an easy problem to fix once notified, but we had to figure it out first. Fortunately, LC cofounder Hannan is pretty handy with electrical work, and got to the bottom of it.

A lot of smaller/mid-sized contractors sub out their electrical work. As the equipment market becomes more competitive, make sure they’re familiar with the brand they work with.

Takeaway: always pass the electrical inspection!

How Long To Fix An Issue?

The vast majority of the time is spent on diagnosis & scheduling. If a service tech catches your issue super quickly, the fix usually doesn’t take very long (unless you’re dealing with a specialized part and you need to wait for the OEM to ship it out to you).

However, if the problem is difficult to diagnose, then you’re dealing with 3 or 4 service visits. Asking a potential contractor if they have an in-house, local service team (or at least service coordinator) is a great way to figure out who’s good and who’s not.

Does Equipment Matter?

Yes. Having a local supply house/strong tech support team means more people to ask technical diagnostic questions to, and easy parts replacements. This is the primary reason why people say that it’s hard to get replacement parts for brands such as Mr. Cool. This is also why a lot of contractors like Mitsubishi.

We’ll publish a report on brands & local supply houses in a month. It’s not just Mitsubishi anymore, but I’d make sure the brand has a strong local supply house presence (e.g. multiple supply houses around Boston metro area).

Which Contractors Best Respond to Service?

If there’s one question you should ask: who responds to the service calls? Is there a dedicated service tech? Is the person coordinating the service response local, and lives close to you?

We’ve found that the biggest difference between more established HVAC contractors (and yes, these include the PE-owned giants) and smaller HVAC contractors tend to be service quality. But this isn’t just a simplistic “big company is good, small company is bad” situation.

Some big PE-backed HVAC conglomerates will incentivize their service techs to just sell new systems, rather than diagnose issues.

However, bigger HVAC contractors will have more back-office operations, which means scheduling tends to be easier & more coordinated.

Some smaller HVAC contractors, typically ones where the owner or a master technician will install the system themselves, will take a lot of care and personally troubleshoot your issues. This is easier particularly if they’re local.

Star ratings are helpful, but like Uber ratings, have limited use because everyone’s a 4.6+ star anyways.

Other things we’ve found out:

VC-backed contractors entering a market will have GREAT customer service for the first 25 to 50 installations, then as executives start focusing on other expansion markets, they take their eyes off the ball.

Personally, I don’t think you need same day service. But I do think you need service within a few days (e.g. 2 or 3). How available contractors are, ultimately, will be a matter of how well the company plans operationally for hot/cold days. You’ll want to make sure you budget extra capacity for the heat waves.

Some Hope on the Horizon

One day, remote monitoring will be built-in to all installed units. And we’d be able to tell with much greater accuracy which contractors consistently have errors pop up with the equipment they register. But of course, this is still very far away; the practical use of such systems is preemptive error detection & remote diagnostics, which helps but is still limited (see: Kumo Cloud error).

As for us, we’re going to bake all of this into our commissioning process for our upcoming Fall 2025 installation deal. And knowing all of this, we’re taking July off specifically to respond to service calls, publish research, & improve our internal processes.

Hope this helps!

This is almost always an air handler unit, b/c mini-split wiring is fairly standardized.

As ever, I appreciate your transparency and always learn a lot from your posts. Thanks for taking the time to observe, learn, document and share your experiences. Huge kudos!

Do you anticipate ever working with the Midea and Gradient cold climate window heat pumps (you know, the saddle style ones)? I have two low load triple deckers and I think they might be a more straightforward and economical option. They're generally designed for easy installation, but having someone do a man J and then getting them up and going would be something that I'd pay for!